Lone Star High Quality Blower and Compressor Accessories

Enhance your blower and compressor systems with Lone Star Turbo’s premium accessories, including inlet air filters, purge panels, regenerative blower filters, and specialized oils. Engineered for performance and reliability, our accessories enhance system efficiency and contribute to long-term operational performance.

Starlube® Synthetic Lubricants

RELIABLE ACCESSORIES

LONG-LASTING PERFORMANCE

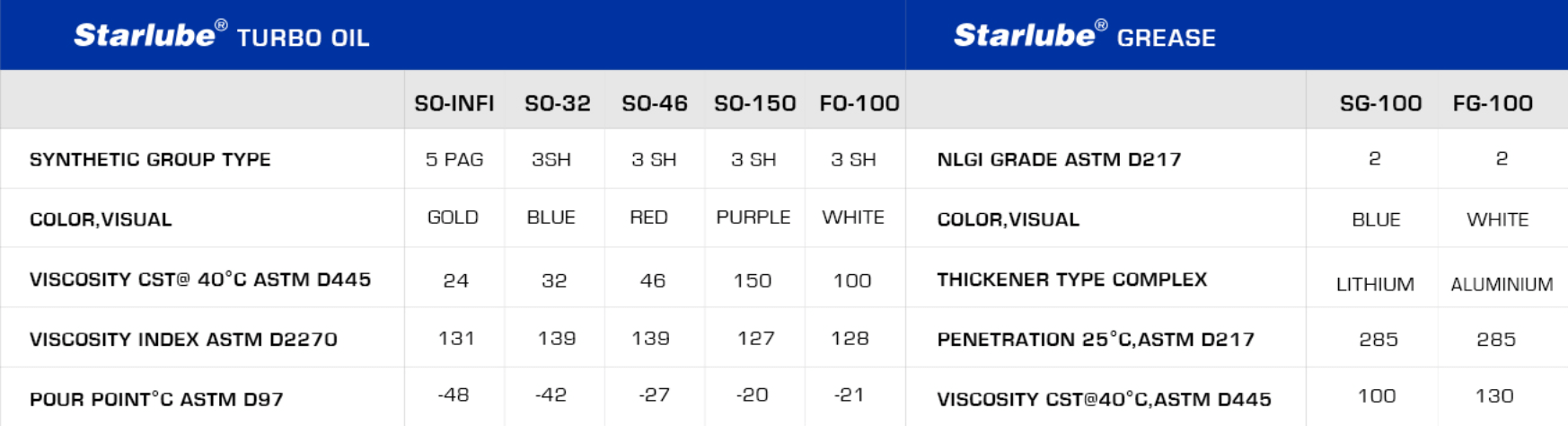

Starlube® Synthetic Lubricants are engineered to deliver optimal performance and long-term reliability for geared and multistage turbo systems.

Designed with efficiency and durability in mind, our lubricants help protect your equipment and reduce downtime. As a leading blower and compressor manufacturer, Lone Star Turbo offers expert guidance on selecting the right lubrication solution for your specific application and environment.

Contact us today to find the best lubricant for your system.

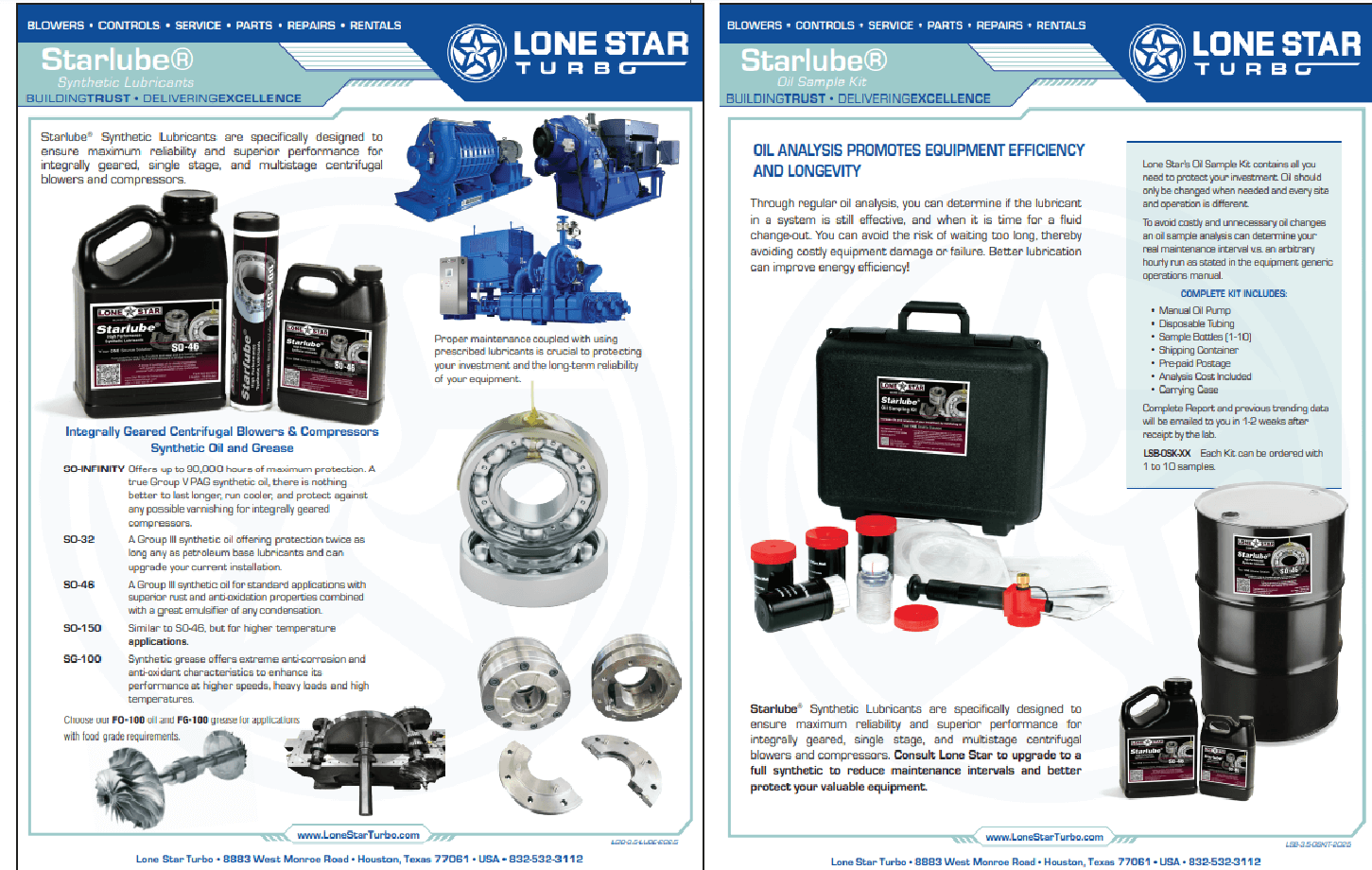

Integrally Geared Centrifugal Blowers & Compressors Synthetic Oil and Grease

| SO‑INFINITY | Offers up to 90,000 hours of maximum protection. A true Group V PAG synthetic oil, there is nothing better to last longer, run cooler, and protect against any possible varnishing for integrally geared compressors. | |

| SO‑32 | A Group III synthetic oil offering protection twice as long any as petroleum base lubricants and can upgrade your current installation. |

| SO‑46 | A Group III synthetic oil for standard applications with superior rust and anti-oxidation properties combined with a great emulsifier of any condensation. | |

| SO‑150 | Similar to SO-46, but for higher temperature applications. | |

| SG‑100 | Synthetic grease offers extreme anti-corrosion and anti-oxidant characteristics to enhance its performance at higher speeds, heavy loads and high temperatures. |

Choose our FO-100 oil and FG-100 grease for applications with food grade requirements.

SAFETY DATA SHEETS

Starlube® Synthetic Lubricants

NOTE: WE SUPPLY OIL IN QUART, GALLON, FIVE GALLON, AND 55 GALLON CONTAINERS. GREASE IS SUPPLIED IN 15 OUNCE TUBES.

Lone Star Oil Sample Kit

Improve Operational Excellence with the Lone Star Oil Sampling Kit

The Lone Star Oil Sampling Kit includes everything you need to collect, package, and send an oil sample for professional analysis—plus, we review the results alongside you.

Regular oil sampling helps detect early signs of wear or contamination, preventing costly repairs and optimizing maintenance intervals based on your specific process and environment.

Each kit comes complete with a durable carrying case, hand pump, disposable tubing, sample jars, a prepaid envelope, and lab analysis included.

Get in touch with Lone Star Turbo today to find the right oil monitoring solution for your equipment.

*Oil and Grease should be changed when required. This is accomplished by sampling & determining the maintenance interval.

• Never mix lubricants or over fill. • Consult your Operations and Maintenance manual for instructions.

Purge Panels

Purge Systems for Gas Seals

PURGING IS THE MOST

RELIABLE LONG-TERM SOLUTION

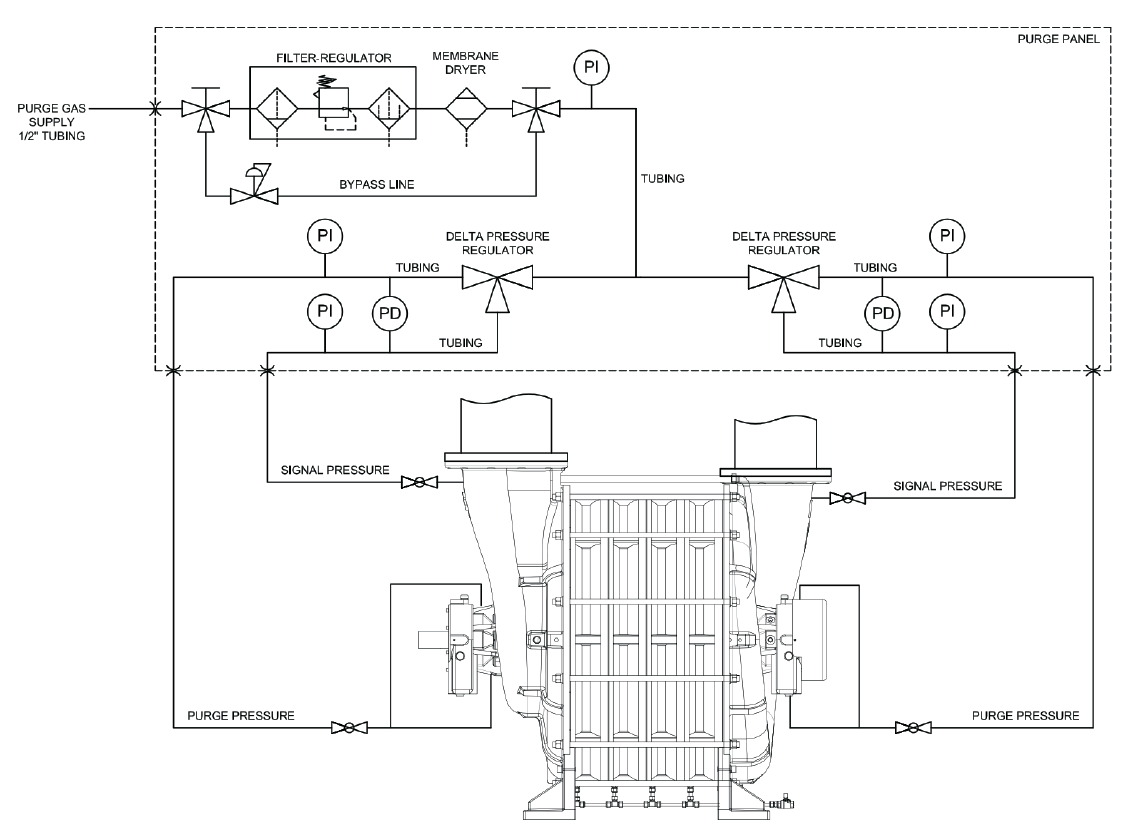

All dry gas seals leak over time, and without intervention, this can lead to increased gas loss and reduced system efficiency. The most effective long-term solution is to introduce a positive pressure purge barrier, which ensures 100% gas sealing while extending the life of the seal by keeping it cool, clean, and dry—without relying on friction.

Lone Star Turbo purge panels are designed for optimal performance with minimal process seepage (typically less than 0.1 cfm). For facilities without a consistent supply of dry instrument-grade purge gas, we offer optional dryer systems capable of reaching a -40°F dew point, or nitrogen membrane dryers to ensure any purge seepage is 99% N2.

Our systems feature a delta pressure regulator that maintains purge pressure just above blower pressure, achieving full process containment with nearly zero seepage. Whether mechanical or fully automated, Lone Star Turbo purge solutions are built for reliability, remote monitoring, and long-term system protection.

- 100% Gas Containment

- Prolongs Seal Life

- Automation adjustments reduce seepage

- Option Filtration for Purge Quality

- Nitrogen Generators and Dryers

- Automated Options with sLOC™ Control Panels

LONG LASTING POWDER-COATED FRAMEWORK WITH STAINLESS STEEL CONTROL PANEL

Purge Panels

Skid or Off Skid Mounted

Simple or Fully Featured

DELTA PRESSURE REGULATION SAVES ENERGY

Maintaining the seal purge pressure just above the process pressure, and automatically adjusting for fluctuations, allows for minimal seepage into the process and therefore less purge gas is consumed

Regenerative Dryer

Reduced Production Costs

Give yourself a competitive edge by reducing production costs with the revolutionary Sahara-Pak. The first to develop a heat-of-compression regenerative dryer, Sahara Air Products has been a leader in

compressed air and gas technology since the 1950’s.

The unique Sahara-Pak uses the normally wasted heat from the compressor to regenerate its desiccant. In addition to efficiently using the heat-of-compression, the Sahara-Pak produces extremely low dew points. An important energy-saving design feature of the Sahara-Pak is the repositioned aftercooler. In order to use the heat-of-compression, the hot air goes directly into the regenerating tower, then to the aftercooler and drying tower. Net result, instrument quality air for free.

A Green Dryer, HOC Requires No CFC’s Does Not Pollute

There are two Sahara-Pak designs that allow you to choose the dryer which best fits your needs. All Heat-of-Compression dryers may only be used with an oil-free compressor; located reasonably close to the compressor. Pipe between the compressor final stage discharge and the Heat-of-Compression dryer should be insulated to minimize heat loss.