Advanced Blower and Compressor Control Panels

MANUFACTURING CUSTOM CONTROL SYSTEMS

FOR CENTRIFUGAL COMPRESSORS & BLOWERS

We manufacture the following types of blower & compressor control panels:

BLOWER & COMPRESSOR CONTROL PANELS

Efficient system performance depends on more than just quality equipment—it requires seamless control and integration. Lone Star Turbo’s One Source Solution combines high-performance local control panels with fully integrated, pre-engineered automation to ensure your blowers and compressors operate at peak efficiency. By managing both the equipment and the process controls in-house, we reduce complexity, improve reliability, and deliver a streamlined solution that maximizes energy savings and long-term performance.

Ensure seamless integration and consistent operation with control panels engineered to enhance both efficiency and reliability.

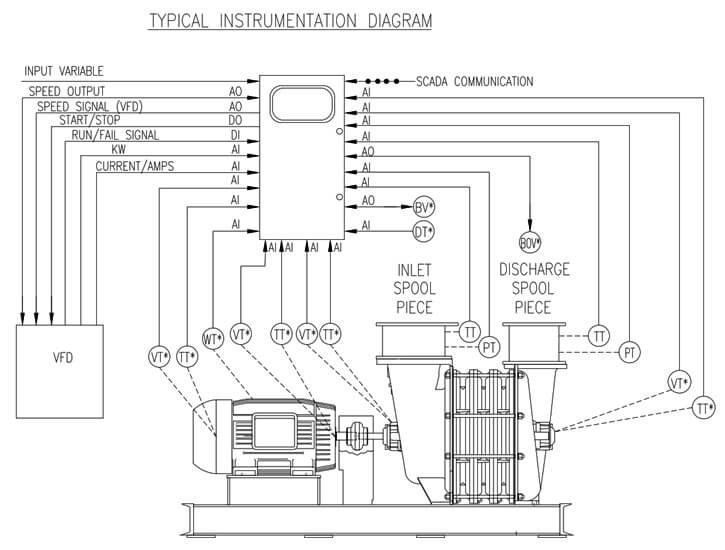

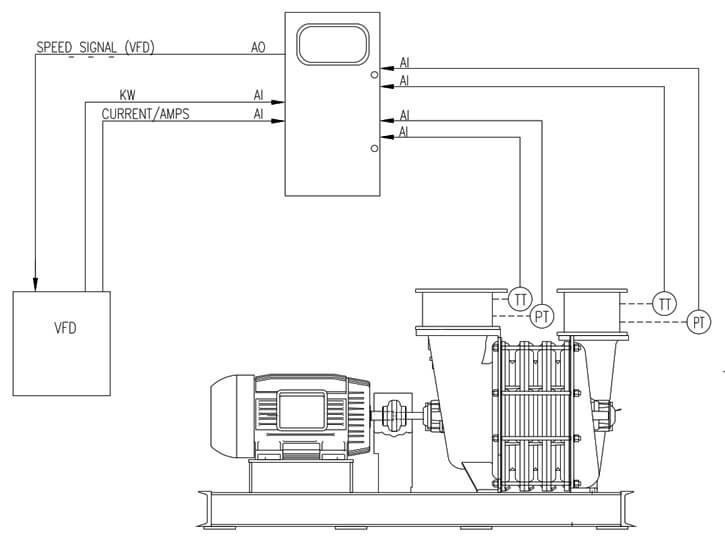

Integrating blower and compressor controls directly with the equipment package enhances automation, improves efficiency, and helps protect your long-term investment. Lone Star Turbo provides custom local control panels for Multistage Centrifugal, Integrally Geared Turbo, Gearless Turbo, Positive Displacement Blowers, and Centrifugal Compressors, ensuring a perfect fit for your application. Whether you need basic system protection or full automation with SCADA or DCS connectivity, our solutions are designed to optimize performance and reliability.

Lone Star Turbo offers expert field service and retrofitted solutions for existing blowers, compressors, and process controls, regardless of brand or technology, helping you improve efficiency, extend equipment life, and reduce downtime.

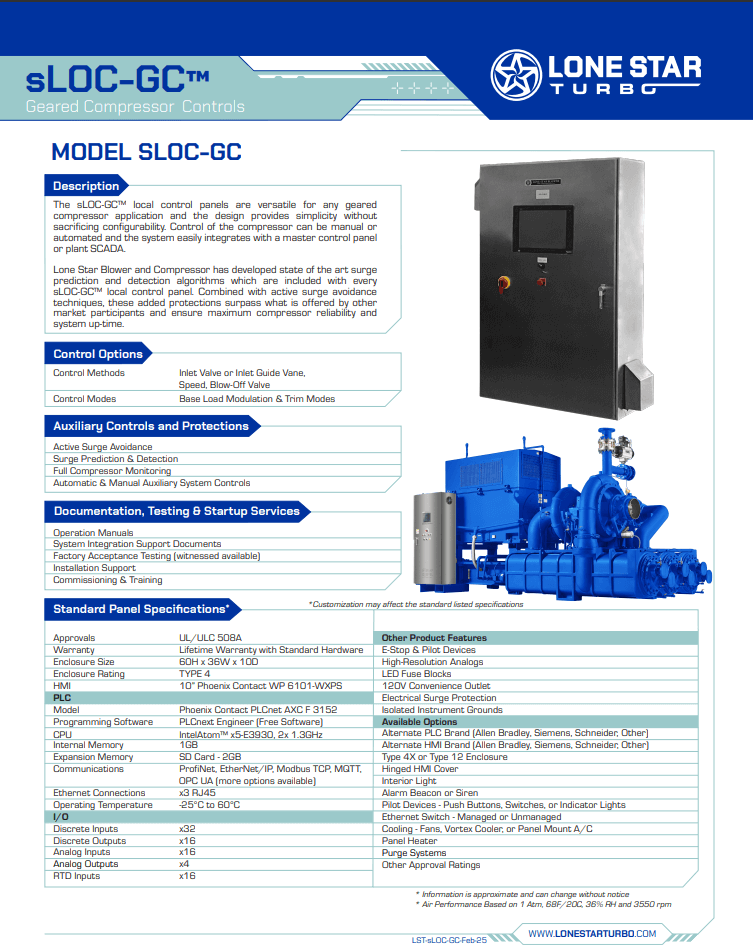

sLOC™ Local Control Panels

Automating your blower or compressor with a local control panel enhances efficiency, reduces costs, and safeguards your equipment by monitoring key inputs like surge, vibration, and temperature. Lone Star Turbo’s panels can include integrated motor starters or variable frequency drives for streamlined installation and simplified integration. Each system is fully tested, pre-engineered, and backed by a comprehensive warranty to ensure long-term reliability and performance.

• Local Control Panel

- Centrifugal Compressors

- Geared Turbos

- Gearless Turbos

- Multistage Turbos

- Positive Displacement

- Centrifugal Compressor

• Networkable

• Pressure or Vacuum Air or Gas

• Can Combine with Motor Starter

• Panels Programmed and Manufactured at Lone Star

• Lifetime Warranty

- No Flow Meter Needed

- Calculates Mass Flow more accurately and more reliably than a flow meter

- Uses Enthalpy equation at inlet and discharge to calculate flow with power and speed

- Entered into a 4th order polynomial equation of the performance curve of the blower and Centrifugal Compressor

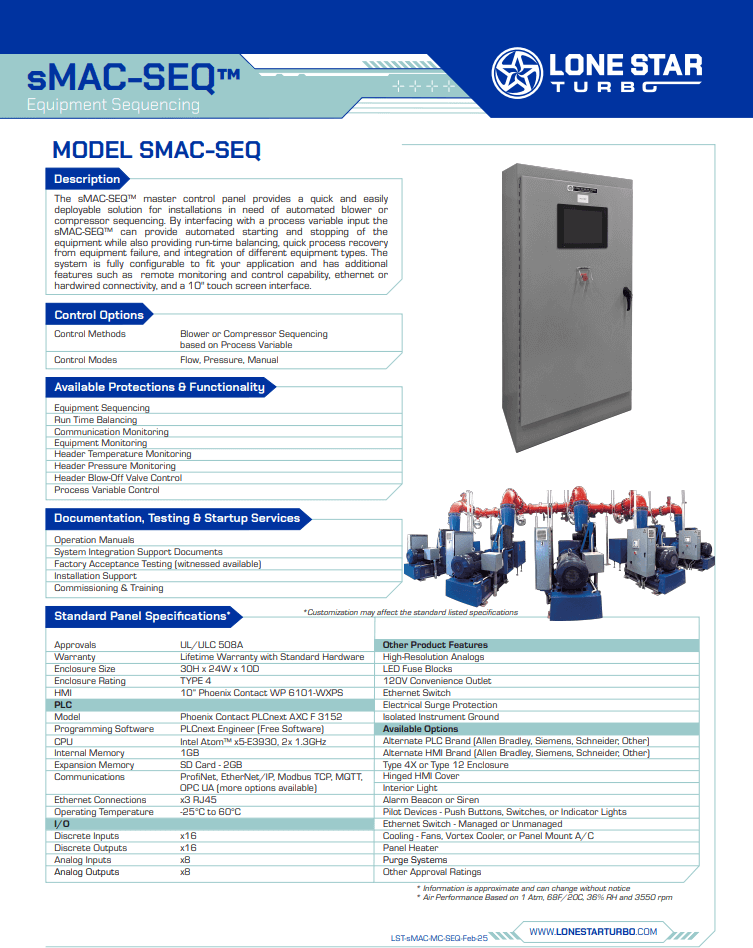

sMAC™ Master Control Panels

FOR TOTAL SYSTEM RESPONSIBILITY

The sMAC™ system offers two distinct levels of master control, each designed to improve overall system performance.

The first level manages organizational control of blowers and Centrifugal Compressors through intelligent sequencing. This includes automated start/stop functions, output modulation to meet system demand, run-time balancing across units, and automatic system restarts after outages—resolving common challenges associated with running multiple blowers on a shared header.

The second level offers full automation of your blower and Centrifugal Compressor process. By integrating sequencing with process valve and instrumentation control, this advanced automation delivers greater system performance and maximized energy savings.

PROCESSING & SEQUENCING CONTROL

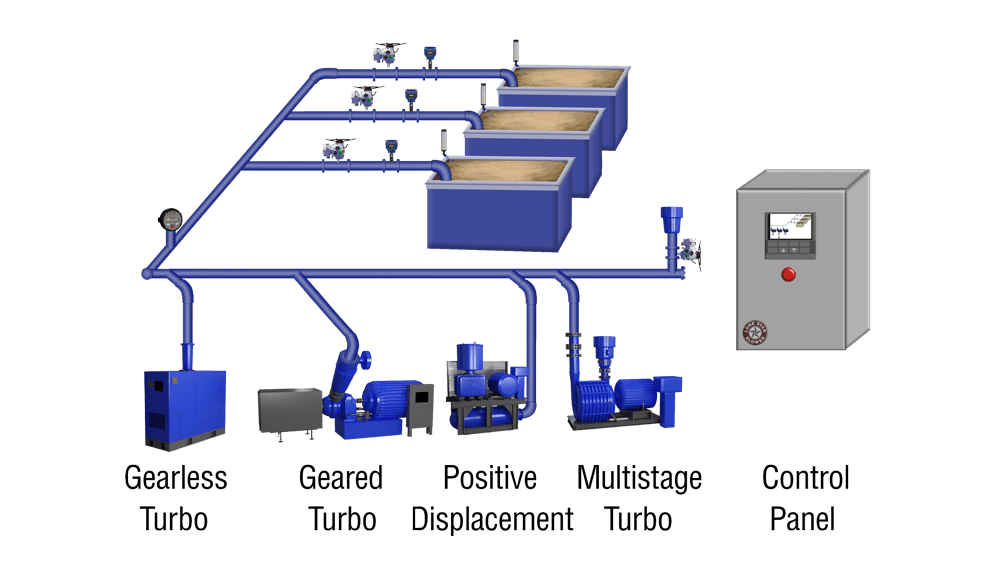

This example shows a three-basin standard aeration system designed for dissolved oxygen monitoring. Lone Star Turbo offers complete turn-key solutions, supplying all equipment shown for efficient and reliable aeration system performance.

Lone Star Turbo provides complete, pre-engineered, and automated process solutions that go beyond basic local blower and compressor control, ensuring seamless integration, improved efficiency, and optimized system performance.

Efficiency Optimization: The sMAC™ sequencing system maximizes energy efficiency by operating blowers and centrifugal compressors within their optimal performance range. Unlike basic control methods, sMAC™ strategically maintains most units at their most efficient “sweet spot,” using only one blower as a variable trim unit to meet system demand without unnecessary energy use.

Lone Star Turbo provides single-point responsibility for complete process automation, including all control hardware, programming, and on-site system integration. The sMAC™ Process Controller not only manages blowers and centrifugal compressors to precise setpoints like flow or pressure, but also responds to critical process variables such as off-gas, ammonia, or dissolved oxygen across multiple points of use—ensuring accurate, efficient, and adaptive system performance.

The sMAC™ system features FOV (Fully Open Valve) control, which uses flow setpoints to reduce header pressure to the minimum required level—directly lowering power consumption and improving energy efficiency. For applications requiring pressure-based control, sMAC™ also supports MOV (Mostly Open Valve) operation using traditional pressure setpoints, offering flexibility to match your specific system needs and performance goals.

Total System Responsibility means Lone Star Turbo delivers a fully integrated, turn-key solution—including blowers, centrifugal compressors, local control panels, motor starters, drives, control valves, flow meters, and sensors such as dissolved oxygen or ammonia probes. By providing complete system integration with a single Master Control Panel, we offer one-source accountability that drives significant energy efficiency and reduces overall capital costs.

Sequencing

Improve system performance and reduce energy costs by operating multiple blowers and compressors with a sequencing panel designed to keep each unit running at its optimal power level. Lone Star Turbo’s integrated control solutions ensure efficient load management and streamlined operation across your entire system.

Process Control

Operate multiple points of use with precision using flow control valves and flow meters that automatically adjust to variable inputs such as pressure, dissolved oxygen, or flow. Lone Star Turbo’s advanced control panels intelligently manage the output of blowers, centrifugal compressors, and valves at each location—ensuring accurate, energy-efficient regulation to meet any process setpoint.

Hybrid Systems

Integrate two blower and compressor technologies on a single common header to optimize energy efficiency and reduce capital expenditures. Lone Star Turbo’s integrated approach allows for flexible system design and performance, delivering cost-effective solutions tailored to your process needs.

We can control any blower and centrifugal compressor technology or a mix of technologies. Let Lone Star Turbo upgrade your existing system.

Complete System Responsibility

Sequencing Multiple Blowers and Compressors

Sequencing Mixed Technologies

Process Control

Aeration is our Specialty

Multiple Control Variables

Multiple Points of Use

- Lower Pressure Means Lower Power Consumption

- 0.5 PSI Average Change is Nearly 5% Total Efficiency Gain

- Even Actively Controlled Pressure Systems Keeps Artificially Higher Pressure to Adequately Control The Blowers and Compressors

sLINK™ Remote Monitoring & Services

All standard sLOC™ and sMAC™ controllers include sLINK™ built in for remote monitoring and troubleshooting directly from the factory or connect to any cloud services

Security: IEC 62443 is the worlds highest standard

TOSIBOX® Allows user to control access

Cloud Based Management – Connect to any Service

Non-Proprietary and Open Architecture

24/7 Data Analysis available

Access from any computer/smartphone/network

sLOC™ and sMAC™

Master Control Panels

For: Geared, Gearless, Multistage, Positive Displacement, Centrifugal Technology

Pre-Engineered and Proven Protection

Easy User Interface

Retrofit Existing Blowers and Compressors

Networkable

Mass Flow Control Option

Completely Automated or Simple Protection

Direct Connection to Control Variable

MOTOR STARTERS AND DRIVES

Lone Star Turbo offers pre-engineered motor starters and variable frequency drives designed specifically to integrate with our blower and compressor systems. These components are plug-compatible with our local control panels, making installation faster, easier, and more reliable while minimizing the risk of integration issues in the field.

As part of our ONE SOURCE SOLUTION, each motor starter or drive is precisely matched to the motor and control system requirements to maximize energy efficiency and system performance. All units are fully pre-programmed, tested, and verified to ensure seamless communication with our control panels—providing a dependable, turnkey solution with complete accountability from design through startup.

Extend your warranty to five years automatically when you purchase the motor and drive together in one optimized package.

Save time and cut installation costs with Lone Star Turbo’s all-in-one, pre-wired control cabinets for blowers and centrifugal compressors, or have our team design a custom solution tailored to your application.

Soft Starter

Solid State Starter

Variable Frequency Drive

Variable Torque or Constant Torque

IEEE519 Compliance for Harmonic Mitigation

UL Certified – All Components

Enclosure Options: NEMA 1, NEMA 12, NEMA 3R, NEMA 4, NEMA 7

Area Classifications: From Non Classified to Class 1 Division 1 or Zone 0 environments