- Emergency Rentals

- Factory Service Overview

- Field Service Overview

- Overhauls

- Aftermarket Lone Star Parts

- Testing and Certifications

- Change Performance

- Controls Service and Upgrade

- System Audits

- Maintenance Contracts

- Remote Monitoring Services

- Drop-in Replacement Blowers

- Drop-in Replacement Compressor

- Service & Maintenance Training

- Lubricants

- New Blowers

- New Compressors

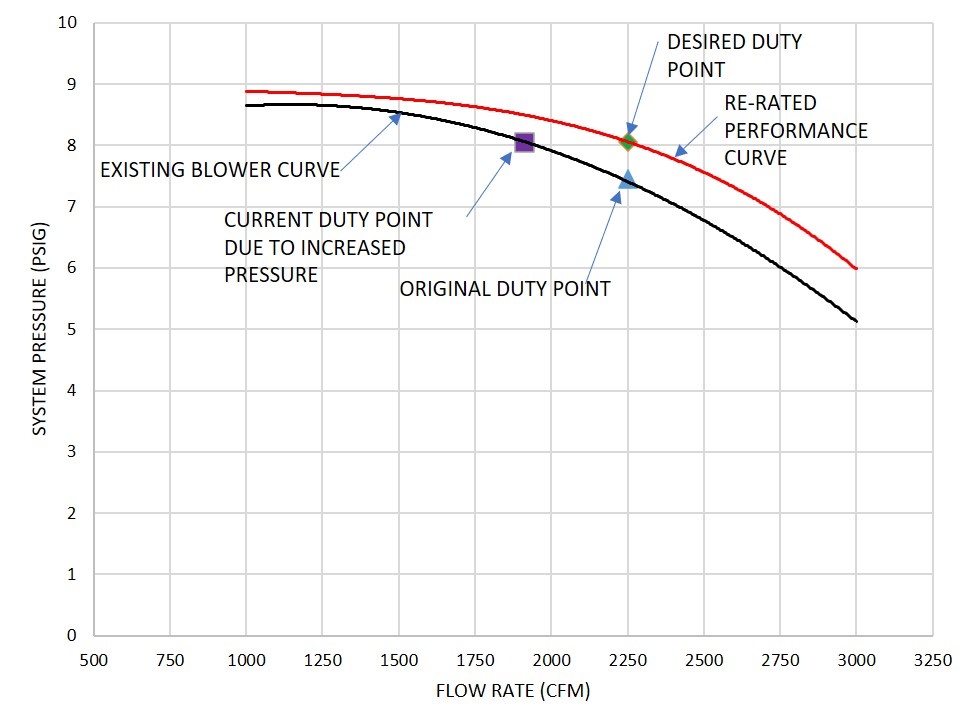

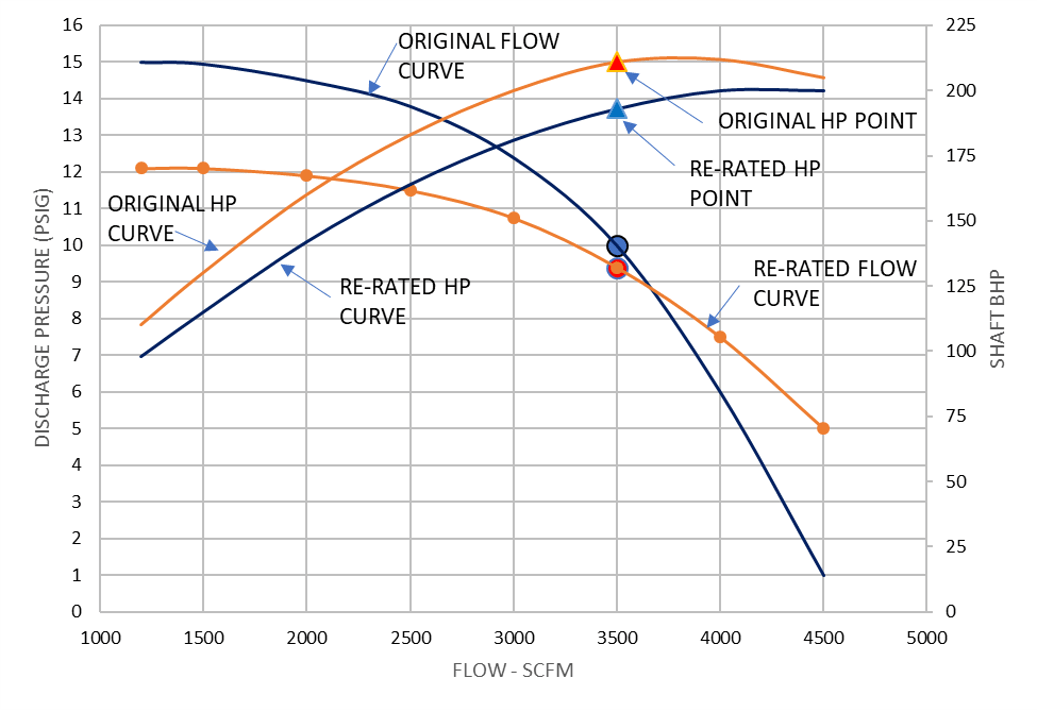

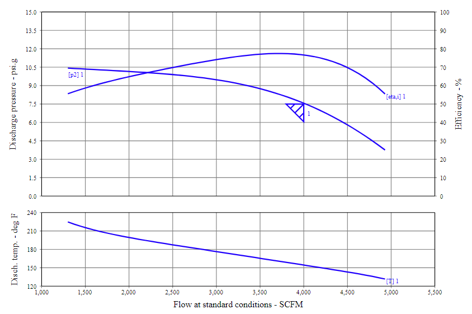

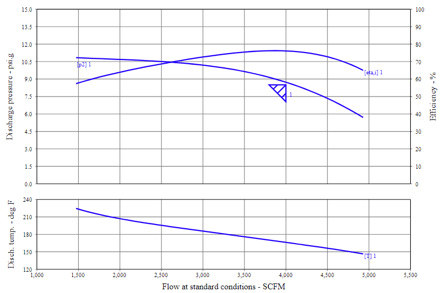

Re-Rating Just Makes Sense: Common Reasons to Re-Rate Your Equipment

EXAMPLE OF INCREASING PRESSURE

80% ARE NOT SIZED PROPERLY

Improperly sized blowers and compressors affect nearly 80% of installations, leading to reduced efficiency, increased energy consumption, and operational stress. Re-rating offers a cost-effective solution by modifying performance characteristics to better match actual requirements. Most re-rates preserve the original unit dimensions, avoiding the need for major piping or layout changes.

Common reasons units are re-rated:

- Increase or Decrease Flow

- Increase pressure rise

- Increase turndown capability

- Increase energy efficiency

Geared Turbo are re-rated:

- Change Gear Set

- Cut Down Impeller

- Add VFD and Controls

Multistage Turbo are re-rated:

- Change Impeller Mix

- Add or Delete Stages

- Change Control to VFD