DT HIGH SPEED GEARLESS TURBO BLOWER

CORE TECHNOLOGY

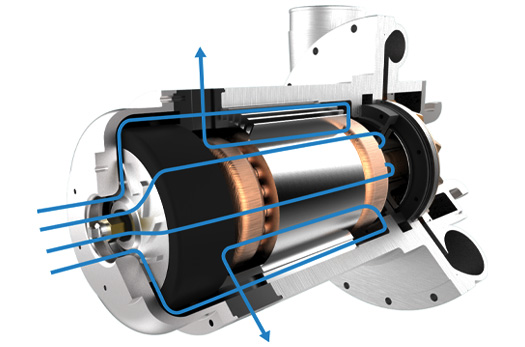

Requires no oil or grease—ever!

Air foil bearing technology, originally developed for military and commercial aviation, has advanced significantly since the 1960s and is now widely adopted across high-speed blower applications. These bearings are simple, durable, and self-acting—requiring no external power, lubrication, or complex control systems to operate. Their low-maintenance design enhances system reliability and supports long-term efficiency in demanding industrial and municipal environments.

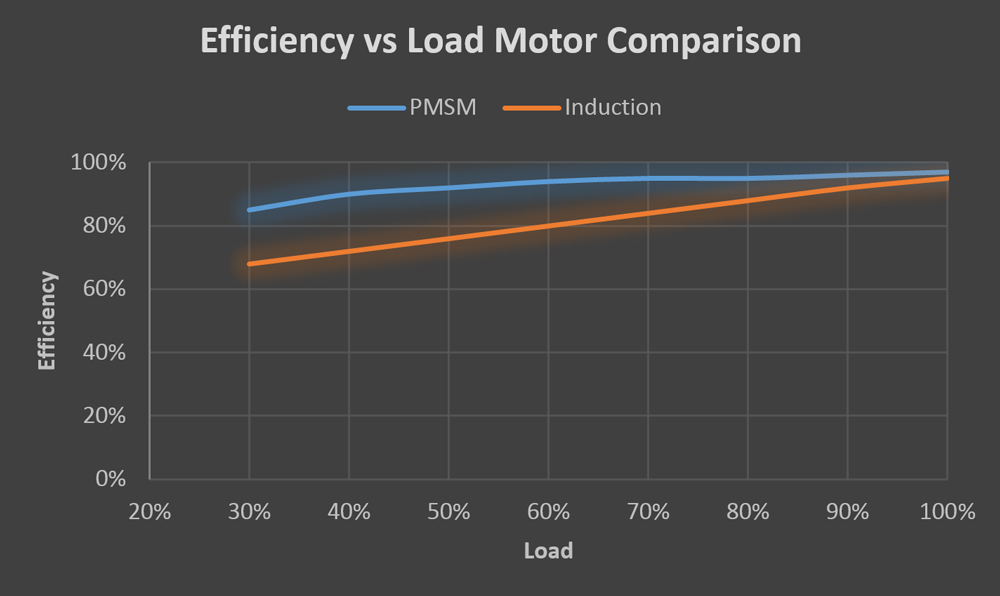

Does not loose efficiency at reduced loads like induction type motors

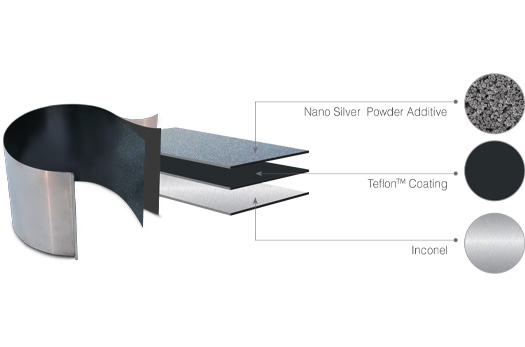

Ensure a high strength-to-weight ratio for high speed operation

Leveraging advanced Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), and precision 5-axis machining, we design and manufacture impellers that maximize efficiency without compromising structural integrity. Each impeller is optimized for high-speed performance with a high strength-to-weight ratio and a backward-swept profile that maintains a strong rise to surge across the full operating range, ensuring stable and efficient airflow.