NEWFOUNDLAND AND LABRADOR BLOWERS AND COMPRESSORS SERVICE

LONE STAR IS YOUR OEM REPLACEMENT

FOR BLOWERS & COMPRESSORS

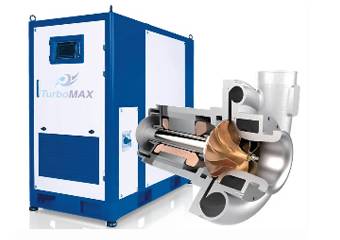

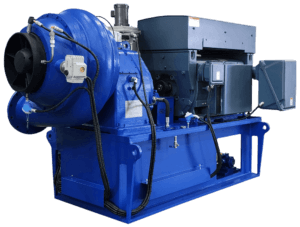

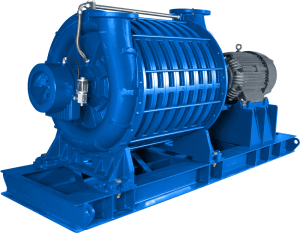

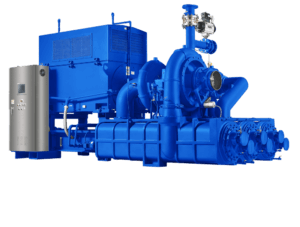

Lone Star manufactures the most advanced centrifugal blowers and compressors in the world, but also offers factory service and repair for your existing equipment better than the OEM!

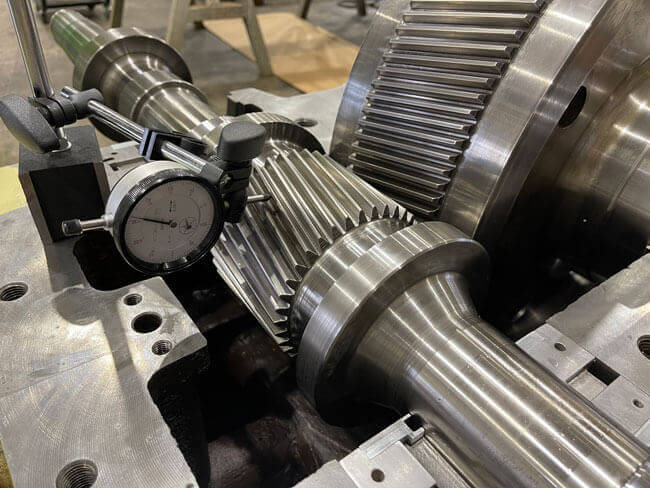

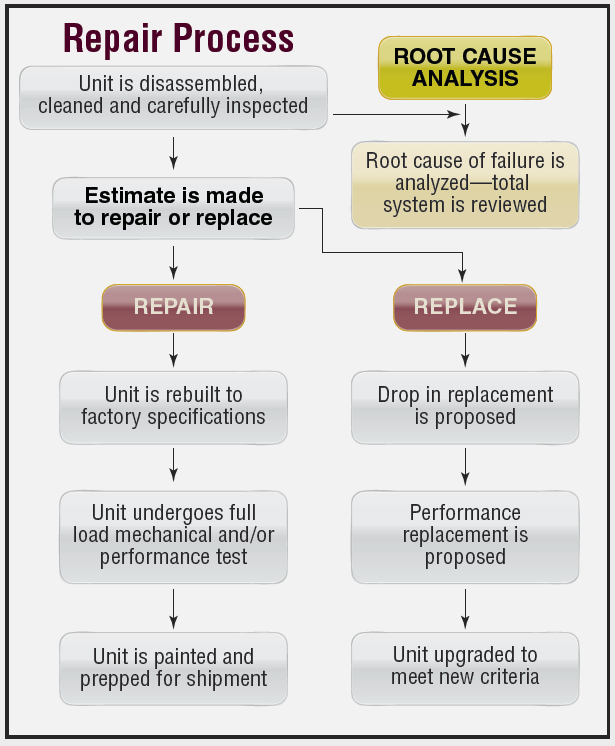

As a blower & compressor manufacturer, our factory specialists are trained in various blower technologies. Our repair process starts with a detailed disassembly and inspection. Beyond a repair, our application engineers work to find out the cause of failure and provide solutions to avoid future downtime.

All repaired or replaced products leave our factory with a same-as-new warranty and are fully run tested to maximum power and pressure to ensure maximum reliability.

Our large stock of Lone Star manufactured parts means faster turnaround for Hoffman, Lamson, Gardner Denver, Atlas Copco, HSi, Turblex, Howden, Siemens, Roots, Continental, Hibon, Spencer, and National Turbine, Ingersoll Rand, FS Elliott, Atlas Copco, Sullair (IHI), and Hanwha Samsung centrifugal blowers and compressors*. Click to find your brand and model. A full 1 year same as new warranty applies to all overhauls.

Detailed disassembly and inspection procedures as well as material root cause analysis can help determine causes of failure and prevent new failures. Lone Star manufactures all parts for these blowers and compressors to allow fast and efficient services.

Our test stand can fully mechanically run blowers up to 4,000 hp. On site capabilities for Balancing , Vibration analysis, complete engineering service, positive material identification, and more. See our complete testing capabilities.

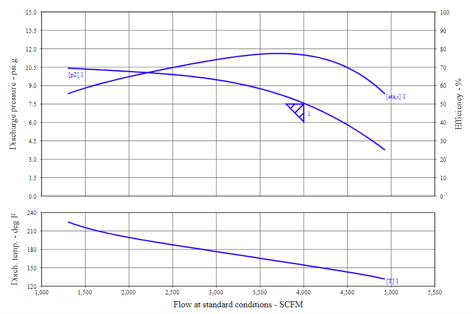

We offer ASME PTC-10 performance testing for blowers to offer positive proof of performance when needed.

We can re-rate performance of your blower by changing, adding or removing impellers, gear ratios, impeller cuts, or adapting a new control system for your existing blower.

Re-rates are changing the performance of the equipment. Majority of re-rates keep the same dimensions.

Re-rates (also known as Performance Change or Change Performance) are changing the performance of the equipment. Majority of re-rates keep the same dimensions.

80% are not sized properly. [80% of what are not sized properly?]

Re-rates are changing the performance of the equipment. Majority of re-rates keep the same dimensions.

We manufacturer and stock parts for fast immediate delivery or can reverse engineer any part to order.

Our experienced technicians can come to you to trouble shoot or do on site repairs or provide maintenance agreements.

Our engineering staff can change impellers, vanes or gears to give your current unit an alternative performance.

Lone Star can manufacture an exact duplicate blower or compressor that is parts interchangeable and dimensionally equal to what you have now.

Upgrade to the most modern and efficient technologies of geared, gearless or multistage turbo blowers and centrifugal compressors from Lone Star.

Lone Star can review your entire blower or compressor system for reliability, energy audits, capacity, control systems, air leaks and more.

Our factory will overhaul and repair your blower or compressor quickly and return it with the same as new warranty as it is full load tested just like new units.

Monthly, Quarterly, or Yearly! Let Lone Star offer a plan to suit your needs. We offer contracts where we completely maintain your equipment on site.

We have a large inventory of blowers ready to ship today or we can build to your performance needs. Air, Gas, Pressure or Vacuum. Short term or long term.

Lone Star builds standard and custom panels and programs to any specification. UL508A Certified.

We buy in any condition and from anywhere.

Lone Star manufacturers and stocks blower and compressor parts for Hoffman Parts*, Lamson Parts*, Gardner Denver Parts*, HSi Parts*, Atlas Copco Parts*, Howden Parts*, Siemens Parts*, HV-TURBO Parts*, Turblex Parts* Single Stage and Multistage Turbo Blowers.

Our in-stock blower parts & compressor parts include:

| FACTORY SERVICE CAPABILITIES |

|---|

| Worldwide Repair |

| Performance Testing ASME PTC13, PTC10, ISO 5389, API |

| Emergency Response Team |

| Test Stand to 6000 hp / 4,500 kw – 13.8kv to 380v / 60-50hz |

| 40 Ton Cranes |

| Hydro Pressure and Leak Testing |

| Overspeed Testing |

| Positive Material Identification – XRF or OES |

| Reverse Engineering – Laser Scan |

| Dynamic Balancing |

| ASME Section 9 Welding |

| Sand Blasting and Painting |

| Specialized Baked-on Coatings |

| Vibration Analysis |

| Lubricant Analysis |

| Rotor Dynamics |

| Change Performance |

| Aerodynamic Analysis |

| Torsional Analysis |

| FACTORY SERVICE CAPABILITIES |

|---|

| Bearing Analysis |

| Overhauls |

| Operator and Maintenance Training |

| 3D Modelling & Design |

| Computational Fluid Dynamics |

| Finite Element Analysis |

| Balancing |

| Magnetic Particle |

| Ultrasound |

| Sound Testing |

| Root Cause Analysis |

| Liquid Penetrant |

| Full Load Test Facility |

| Hydrostatic Testing |

| Overspeed Testing |

| Performance Test ASME, API, ISO |

| Positive Material Identification |

| Sandblast and Paint |

| Door-to-Door Service |

| RS Logix, Siemens, Modicon, Other Interface Software |

| Predictive Maintenance |

| FIELD SERVICE |

|---|

| System Audits |

| Preventative Maintenance |

| On-Site Repair |

| Troubleshoot & Root Cause Analysis |

| Control System Services |

| Software Upgrades |

| Vibration & Power Analysis |

| Laser Alignment |

| Start-up & Installation |

Lone Star specializes in dynamic compression of geared, gearless and multistage centrifugal blowers and compressors from Hoffman, Lamson, Gardner Denver, Atlas Copco, HSi, Turblex, Howden, Siemens, Roots, Continental, Hibon, Spencer, National Turbine, Ingersoll Rand, FS Elliott, Atlas Copco, Sullair (IHI), and Hanwha Samsung and other brands*.

Lone Star Turbo’s Factory Headquarters is in Houston, Texas and is equipped to provide single stage and multistage turbo blower, and compressor service, parts, repair, and rebuild services throughout North America and South America.

Click on your State, Providence, or Territory below to learn how we can assist you!

Click on your blower & compressor manufacturer and scroll down to your model number

(if you do not see your specific brand or model please call our experts now at 832-532-3112 or submit a request for quote.)