Positive Displacement Blower Rentals Air or Gas, in Pressure and Vacuum Applications

Positive Displacement Blower Solutions

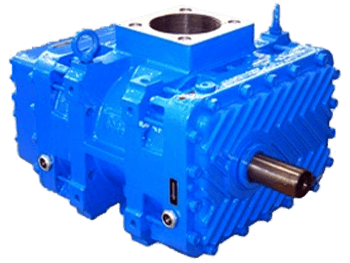

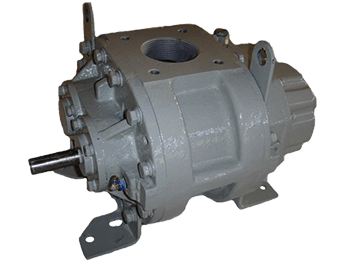

OEM REPLACEMENT BLOWERS

| OEM Series | We have drop in replacement blowers in stock to replace Roots*, Gardner Denver*, Sutorbilt*, Tuthill*, Eurus*, Aerzen*, and Kaeser* Positive Displacement Blowers. |

|---|---|

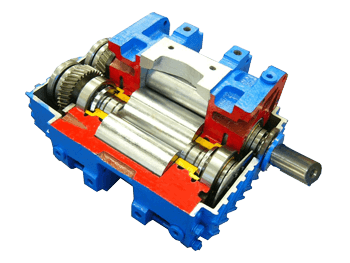

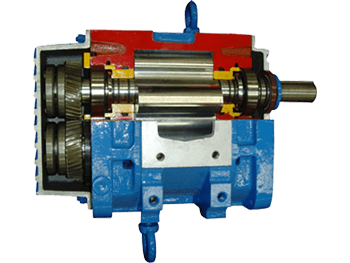

| Tri-Lobe Series | These are modern low pulsation blowers are fitted with latest gear and seal technology |

| Bi-Lobe Series | Our quick ship models have a capacity from 250 to 3,000 cfm and are design for long life. |

| Engineered | We can build the world’s largest positive displacement blower to over 44,000 cfm. Call us today with your application. |

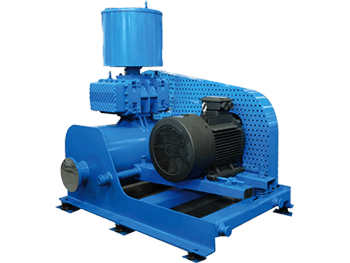

| Packaged | We have quick ship PD Blower Package Rentals and PD Vacuum Package Rentals to deliver within a few days or we can custom package to meet any specification. |

to offer an energy analysis and site survey at your location to see if you qualify for a no obligation trial in your facility.

What is the difference between a Roots blower and a Turbo blower?

TURBO BLOWER

ROOTS BLOWER

Engineered to provide Class 0 oil-free air up to approximately 15 psig, a positive displacement blower is specifically designed with rotary lobe technology. These machines, often air-cooled and lacking an aftercooler, exhibit resilience across diverse flows and operating conditions. Their seamless integration is facilitated by easy installation, commissioning, and initiation through local plant resources.

In numerous rental scenarios, opting for a positive displacement blower with a Variable Frequency Drive (VFD) proves optimal, offering versatility, energy efficiency, and straightforward installation and operation, particularly for oil-free applications below the 15 psig threshold.

Roots blowers deliver a relatively constant volume of air at varying pressures. In contrast, a turbo blower (centrifugal blower) uses a high-speed impeller to impart velocity to air or gas.

Considerations When Choosing PD Blower Packages

- Application

- Energy efficiency

- Noise reduction

- Required airflow volume

- Operating pressure

- Altitude and temperature

To prevent premature failure, it’s important to use the right lubricant and meet equipment specifications. High-performance lubricants can extend the lifespan of bearings and gears.

Key Applications

| Wastewater Treatment | Positive displacement blowers are integral in aeration systems for wastewater treatment plants. They provide the necessary air for biological processes that facilitate the breakdown of contaminants. |

|---|---|

| Pneumatic Conveying | In industries like food and beverage, positive displacement blowers are used for pneumatic conveying systems. They help transport bulk materials efficiently and hygienically. |

| Chemical Processing | Positive displacement blowers play a vital role in chemical processing applications where a consistent and controlled flow of gases is essential. This includes processes such as chemical vapor deposition and gas boosting. |

| Oil and Gas Industry | These blowers find application in the oil and gas sector for tasks like vapor recovery, gas boosting, and flare gas systems. They contribute to maintaining optimal operational conditions. |

| Aeration in Aquaculture | Positive displacement blowers are utilized in aquaculture systems to provide aeration for fish tanks. This ensures proper oxygen levels for the aquatic environment. |

| Printing Industry | In printing, these blowers are employed in sheet-fed offset printing machines to maintain precise control of air flow for drying inks. |

| Medical and Healthcare | Positive displacement blowers are used in medical equipment, such as vacuum pumps for suction applications in hospitals and laboratories. |

| Power Plants | They are employed in power plants for processes like pneumatic ash handling systems, aiding in the efficient disposal of ash generated from combustion. |

| Vacuum Systems | Positive displacement blowers are integral components in various vacuum applications, including packaging, where a controlled and consistent vacuum is required. |

Why Choose Lone Star Rental?

RENTALS in the Americas & Beyond:

Click on your State, Providence, or Territory below to learn how we can assist you!