System Audits That Deliver Results

Lone Star Turbo provides in-depth system audits and performance assessments for air, gas, pressure, and vacuum blower or compressor applications. These engineered evaluations help improve system reliability, reduce energy costs, and support planning for future expansion or process changes.

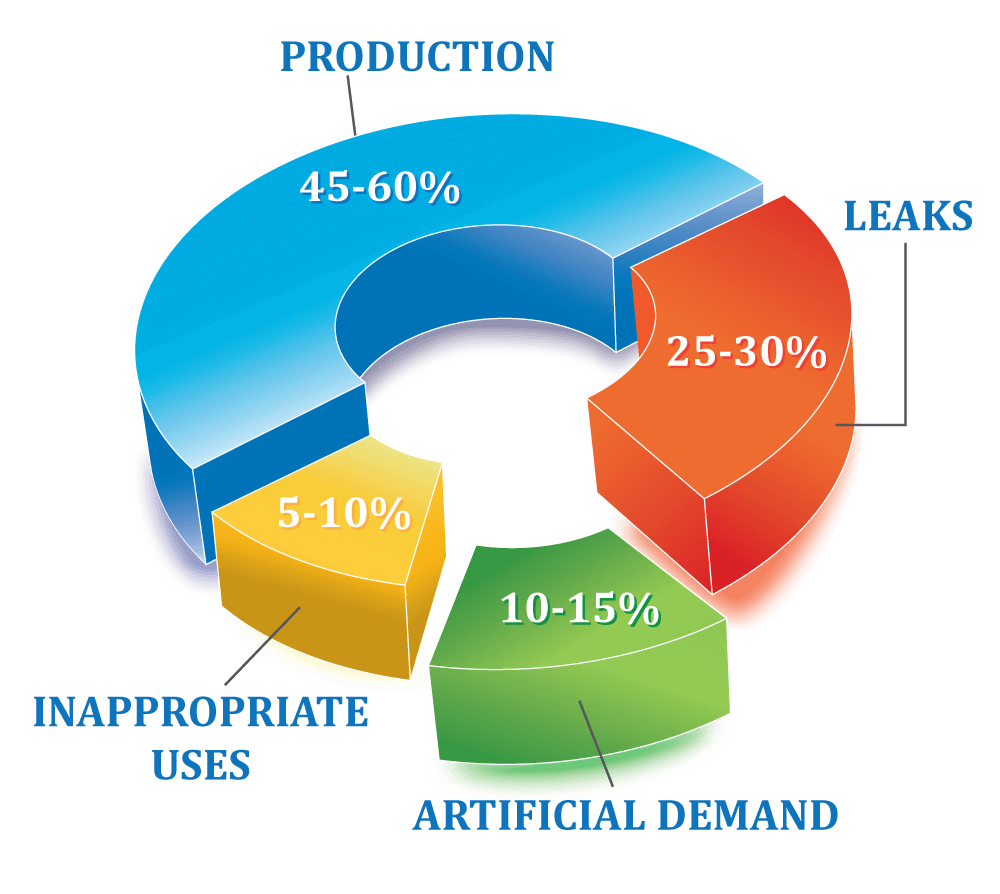

Plant operations often evolve over time—yet blower and compressor systems are rarely adjusted to match changing demands. Our audits regularly uncover performance issues, as nearly 80% of blowers are initially mis-sized and many compressors waste up to 50% of the air they generate. Most clients see a full return on investment within months.

Our evaluations go beyond equipment condition, focusing heavily on control systems—both local unit control and how systems integrate with your overall process. This gap between equipment and operations is often the biggest opportunity for long-term energy savings.

TYPES OF AUDITS

ASSESSMENT

Simple walk through and make general observations as to best practices by an experienced engineer.

COMPRESSED AIR AUDIT

These are very detailed evaluation that takes days or even weeks and often includes data logging and sample measurements.

- To Identify known Issues

- When considering expansion or reductions

- Low System Pressure

- Moisture Problems

- Piping – Transmission Problems

- Reliability Issues

- Controllability Issues

- Identify Artificial Demand

- Optional Data Logging Audit

LEAK DETECTION

Often exceed 30% of produced Air!

ENERGY EVALUATION

Discover The True Cost of Operation

- Misappropriate Use of Compressed Air

- Optional Data Logging

- Identifying Mis-sized Equipment

- Identifying Payback Opportunities

Contact Lone Star Turbo

Lone Star Turbo can field service or retrofit your existing blower or compressor and process control no matter the brand or technology.