Efficient Aeration Blower Solutions for Water & Wastewater Treatment

AERATION BLOWERS FOR WATER AND WASTEWATER NEED ENERGY EFFICIENCY AND RELIABILITY

Lone Star Turbo designs, manufactures, and services a full range of centrifugal blower and compressor technologies—including geared, gearless, and multistage turbo systems—along with integrated control systems. With multiple technologies available, we tailor energy-efficient solutions to meet the specific needs of each water and wastewater treatment application. Because no two processes are alike, we provide flexible options that optimize performance, cost, and reliability. Our turnkey approach includes process integration and control for complete system accountability.

We support a wide range of aeration and treatment processes, including basin aeration, air scouring, digester gas handling, filter backwash, grit chamber aeration, lagoon systems, SBR (sequential batch reactors), and MBR (membrane bioreactors). Lone Star also offers comprehensive aftermarket services for ongoing support, repair, and optimization of your existing blowers and compressors—regardless of brand.

Proper blower selection and aeration system design are critical for wastewater treatment efficiency. With aeration accounting for up to 60% of a plant’s energy usage, optimizing flow and pressure is essential. Our team ensures you get the right solution to reduce energy consumption and deliver reliable performance over time.

Aeration Basin

In the aeration basin, microorganisms consume oxygen and organic pollutants, generating biomass and releasing carbon dioxide. This biological process is a fundamental step in effective wastewater treatment. Lone Star Turbo supports this vital function with engineered aeration blower systems designed for long-term efficiency and reliability. Our fully integrated solutions include precision process control, energy-efficient technologies, and customized system designs tailored to various biological treatment applications such as activated sludge, Sequencing Batch Reactors (SBRs), nitrification-denitrification processes, and Membrane Bioreactors (MBRs). Properly optimized aeration systems ensure consistent treatment performance, reduced energy usage, and compliance with environmental regulations.

Air Scouring

Air scouring is a cleaning process that forces large volumes of filtered compressed air through water in a pipeline, creating slugs of air and water that dislodge sediment, debris, and biofilm buildup. These slugs enhance internal cleaning efficiency by scouring the pipe walls, while the air is then vented outside to complete the cycle. This method helps maintain optimal flow, preserves system integrity, and extends the operational life and hygiene of the pipeline network.

Municipal Water Aeration

Aeration treatment works by directing large volumes of air through water, allowing oxygen to interact with dissolved gases and volatile compounds. As the air moves through, it strips away these contaminants, carrying them upward. The contaminated air is then vented safely outside, making this process effective for purifying water and improving overall treatment efficiency.

Digester Gas

Biogas, which consists of mainly methane and carbon dioxide, is a potent greenhouse gas produced by the breakdown of organic waste. Municipal anaerobic digesters are designed to capture and contain these gases, preventing harmful emissions into the atmosphere. Typically, organic feedstocks in wastewater treatment would release methane if allowed to decompose in open lagoons or landfills.

Filter Backwash System

A backwashing filter is designed to capture suspended particles from water using a tank filled with specialized filtration media. During the backwash cycle, the flow of water is reversed and accelerated, dislodging trapped contaminants and flushing them out of the system. This process ensures consistent filtration performance and prolongs the life of the system.

Grit Chamber Aeration

An aerated grit removal system removes particles by forcing water that has passed through bar screens into a grit chamber, which has air pumped into it.

Aerated Grit Chambers in Wastewater

Municipal wastewater systems rely on aerated grit chambers to remove abrasive particles early in the treatment process. Air is injected along one side of the tank, inducing a spiral flow that separates heavier grit from lighter organics. The grit settles at the bottom for removal, while lighter particles remain suspended in the flow and are carried out of the tank for further treatment. This process helps protect downstream equipment and improves overall plant efficiency.

Wasterwater Treatment System

Wastewater treatment is the process of removing contaminants from industrial or municipal wastewater to produce an effluent that can be safely returned to the environment or reused. Once discharged back into the water cycle, this treated effluent creates minimal environmental impact or is repurposed through water reclamation for uses such as irrigation, industrial processes, or groundwater recharge. By meeting strict regulatory and environmental standards, wastewater treatment plays a vital role in supporting water conservation and long-term sustainability.

Sequential Batch Reactor Wastewater

A Sequencing Batch Reactor (SBR) is a fill-and-draw activated sludge system used for municipal and industrial wastewater treatment. Wastewater is introduced into a single batch reactor, where it undergoes aeration, settling, and decanting phases to remove organic matter, nitrogen, and other contaminants. SBR systems are highly flexible and ideal for varying flow rates or limited space applications.

Membrane Bioreactor (MBR)

A Membrane Bioreactor (MBR) is an advanced wastewater treatment technology that integrates membrane filtration—typically microfiltration or ultrafiltration—with the biological activated sludge process. This combination allows for the efficient removal of organic and inorganic contaminants, producing high-quality effluent that meets stringent discharge or reuse standards. MBR systems are widely used in both municipal and industrial facilities, especially where space is limited or water reuse is critical. Compared to conventional systems, MBRs offer a smaller footprint, greater process control, and enhanced solids separation.

Blowers for Wastewater Treatment

Blowers play a critical role in wastewater treatment by delivering the airflow required for aeration in activated sludge systems and aerobic digestion processes. They help maintain proper mixing, keeping solids suspended in aeration basins, channels, and aerated grit chambers—ensuring effective biological treatment and system stability.

Aeration Blower Function / Aeration Blowers Wastewater

While the blower’s primary function is to generate airflow, the role of blower controls is to regulate that airflow precisely to meet process demands. Optimized blower controls enhance aeration efficiency by delivering the exact amount of air at the right time, reducing energy waste and supporting reliable wastewater treatment performance

Sewage Sludge Incineration

A Sewage Sludge Incinerator (SSI) is a combustion system used at wastewater treatment facilities to thermally process dewatered sludge, significantly reducing its volume and converting organic material into inert ash. The two most common types of SSIs are Multiple Hearth Furnaces (MHF) and Fluidized Bed Incinerators (FBI), both designed for efficient waste reduction and reliable thermal treatment in municipal and industrial applications.

Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) is a type of biological treatment system that enhances the traditional activated sludge process. Designed for efficiency and compactness, MBBR uses suspended biofilm carriers to treat wastewater effectively, making it suitable for facilities of all sizes.

Lagoon Aeration

An aerated lagoon is a simple wastewater treatment system that uses mechanical aeration to introduce oxygen and maintain mixing, supporting the biological breakdown of organic matter. With proper aeration and retention time, these systems can achieve high treatment efficiency, making them a reliable choice for municipal and industrial wastewater applications.

Air and Gas Applications for Water & Wastewater Treatment Aeration Blower Solutions

- Aeration Blower

- Aeration Blowers

- Wastewater Blowers

- Air Blowers for Sewage Treatment

- Air Blower for Water Treatment Plant

- Blowers for Wastewater Treatment

- Aeration Blower Function

- Aeration Blowers Wastewater

- Aeration Blower Design

- Air Blower for ETP Plant

- Municipal Water Aeration Systems

- Aeration Blowers Wastewater

- Aeration Blowers for Water and Wastewater Treatment

- aeration blowers wastewater treatment

- Aerated Grit Chamber

- Gas Boosters for Anaerobic Digestion

- Basin Aeration

- Air Scouring

- Digester Gas

- Filter Backwash

- air blower used in water treatment plant

- Grit Chamber Aeration

- Lagoon Aeration

- Wastewater Treatment

- SBR – Sequential Batch Reactor

- MBR – Membrane Bioreactor

- Aerated Grit Chambers

- Wastewater Blower

our products

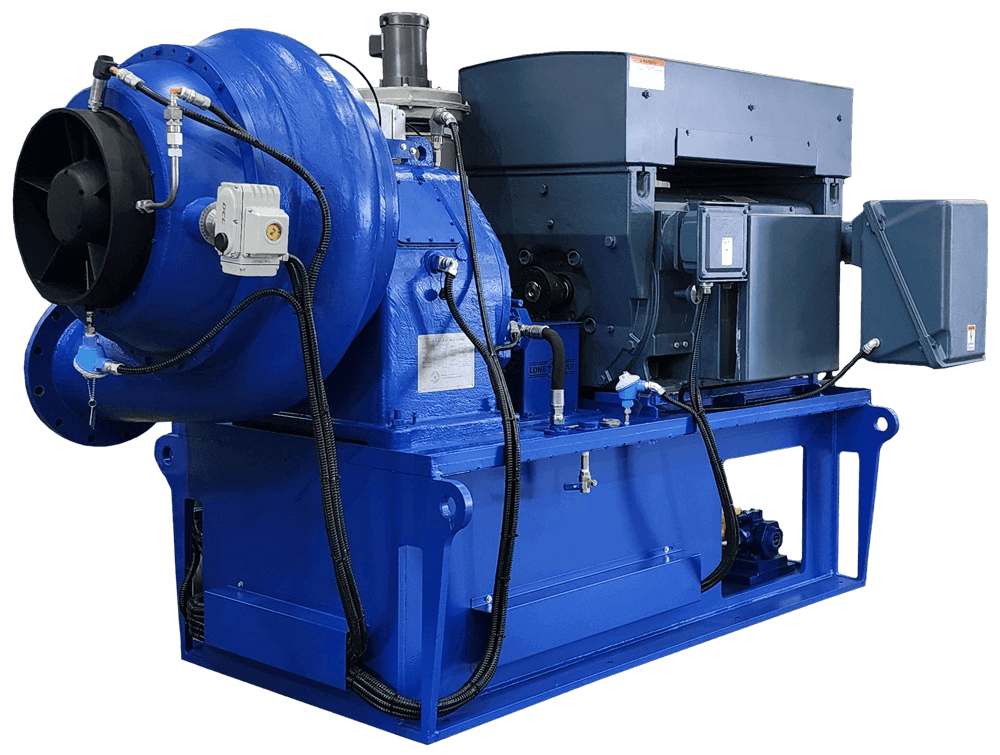

GB SINGLE STAGE GEARED

GB SINGLE STAGE GEARED

Air, Gas, Pressure, Vacuum

Power: 100 – 6,000 HP

75 – 4,500 kW

Flow: 1,000 – 88,000 SCFM

1,700 – 150,000 nm3/h

Pressure: 2 – 35 PSI

0.1 – 2.4 bar

API 617/672

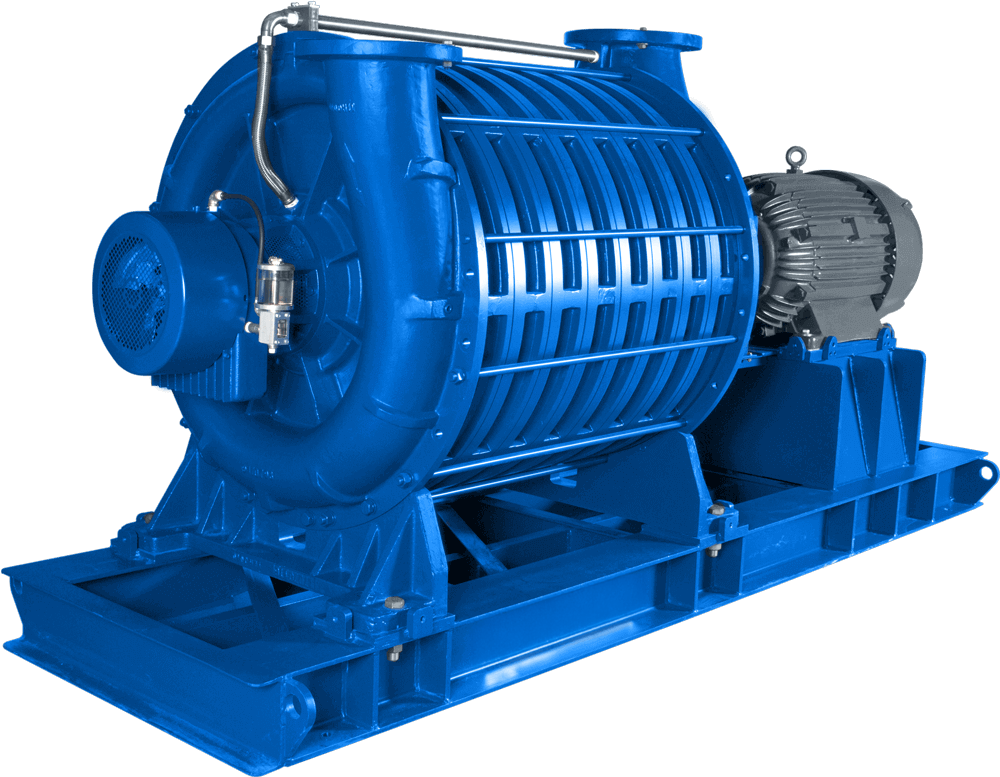

MC Multistage Blowers

MC MULTISTAGE BLOWER

Air, Gas, Pressure, Vacuum

Power: 20 – 3,500 HP

15 – 2,500 kW

Flow: 300 to 45,000 SCFM

500 to 75,000 nm3/h

Pressure: 2 – 25 PSI

0.1 – 1.7 bar

DT HIGH SPEED TURBO

DT HIGH SPEED TURBO

Air, Pressure

Power: 20 – 500 HP

15 – 375 kW

Flow: 150 – 15,000

SCFM250 – 25,000 nm3/h

Pressure: 2 – 20 PSI

0.1 – 1.4 bar

CS Control System

CONTROL SYSTEMS

sLOC™ Local Control Panels forBlowers and Compressors

sMAC™ Process and SequencingMaster Control

AM AFTERMARKET SERVICES

Factory & Field Service

Start Up Service

Overhauls

Preventative Maintenance

Rebuild & Repair

Full Load Testing & Certifications

System Audits

Re-Rating Performance

Root Cause Analysis

Rental Equipment

Emergency Response/Rentals

Direct Replacement Drop-In

Starters & Control Panels

Parts & Accessories

Lubricants

GC Centrifugal Compressor

GC GEARED COMPRESSOR

Air, Gas, Pressure

Power: 200 hp – 13,000 hp140 kW – 10,000 kW

Flow: 1,250 cfm – 350,000 SCFM

2,100 m3/h – 600,000 m3/hr

Pressure: 30 – 1,100 PSI

2 bar – 80 bar

API 614/617/672