Lone Star Turbo’s GC Series Integrally Geared Centrifugal Compressors are engineered for energy efficiency, long-term durability, and superior performance in demanding applications. With over 1,100 successful installations worldwide, Lone Star delivers proven reliability backed by deep industry experience. Each compressor is fully supported from our Houston, Texas manufacturing facility, offering complete field service, factory repair and overhaul, custom packaging, and comprehensive mechanical and performance testing to meet your exact requirements.

High efficiency & optimal design for the best performance

- 5-axis milled backward leaning blade

- Wide operation range with maximum turn down

- Optimized aero-matching through whole flow path

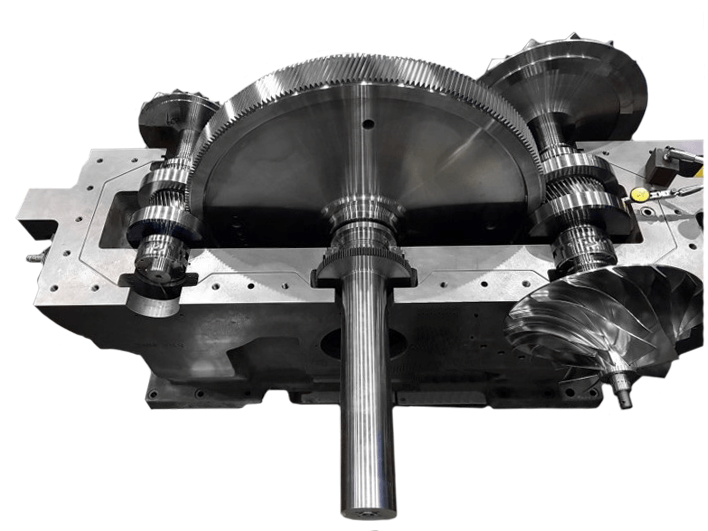

High performance, reliable, and easy maintenance gear system

- Low noise & high precision helical gear

- AGMA 6011/API standard design

- Compliant to DIN3961 Q4/Q5

- (AGMA2000 13/12)

- Individually replaceable pinion and bull gear

- Thrust collar design

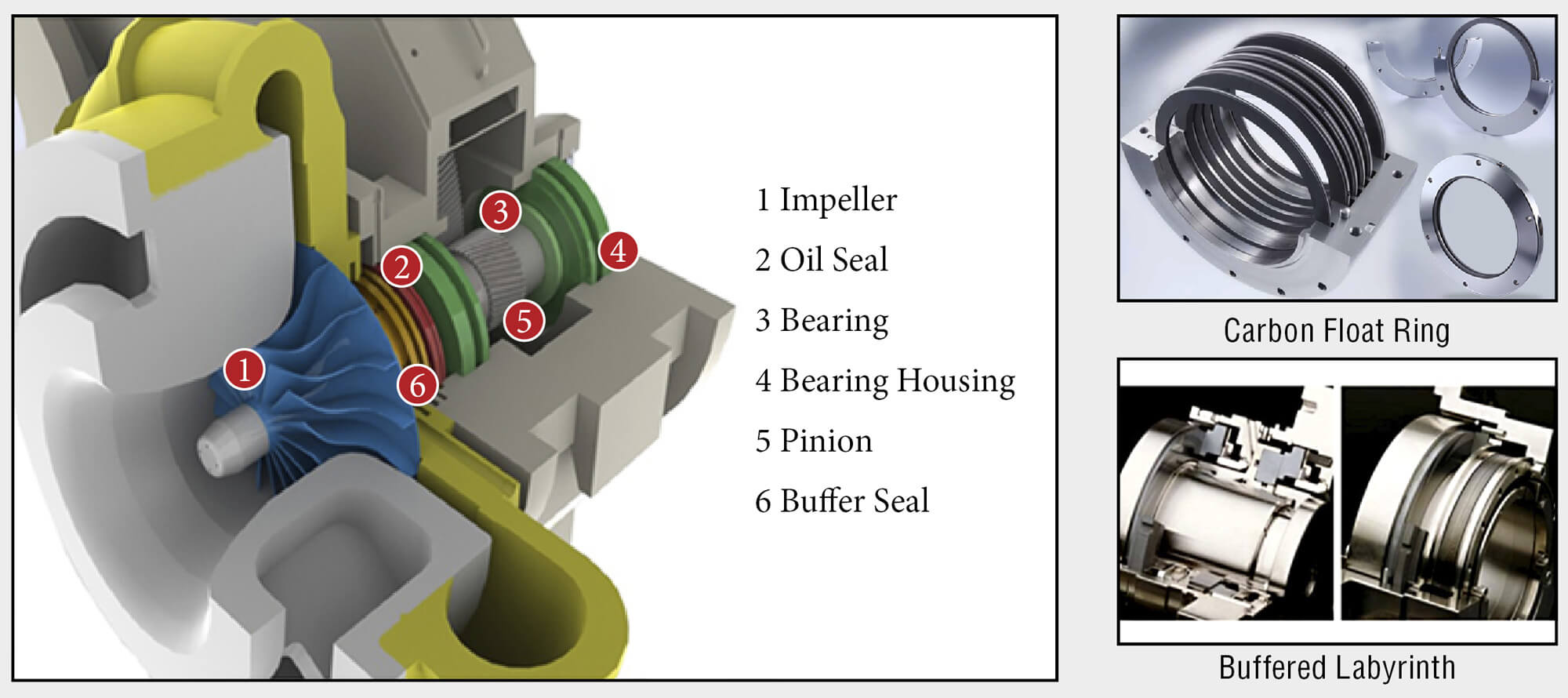

Maximum bearing load capacity & minimum mechanical loss design

- Tilting pad pinion journal bearing

- Sleeve journal and taper land thrust bull gear bearing

- Horizontally split design for easy maintenance

- Designed for maximum static and dynamic load capacity

sLOC™ Control Panel

- Operation status display for control, monitoring, trending and protection

- sLINK™ Remote Monitoring Optional

- Mass Flow Control for wider turndown

- Non-propriety open architecture with options for Allen Bradley, Siemens, or other as required

- 10 Year Warranty on all components with standard control offering